Logigrade Inc

advanced automation with informative documentation

We provide advanced automated systems with newer technologies, user friendly operator interfaces, remote management tools and informative schematics and documentation for ease of operation and maintenance.

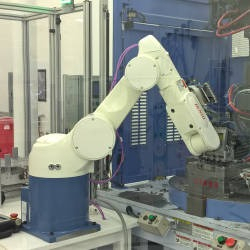

Robotics

Modern motion control systems replace repetitive labor tasks and produce consistent accuracy that is impossible to attain with manual systems.

Use of motion control systems has many benefits including increased productivity, reduced wastage, greater accuracy, reduced downtime, less manpower and reduced maintenance.

Discuss your application with us to see if you can reduce the final cost of your product by using motion and robotics.

We have extensive experience in motion controls and robotics. In our projects we use variety of products to achieve the best results:

- Variable frequency drives

- Stepper motors

- Servo systems

- XYZ systems and Tabletop robots

- SCARA robots

- Flexible 6-axis robots

machine vision

Today's production engineers are constantly striving to produce the highest volume of output with the minimum number of defects possible. Traditionally, end-of-line inspection would be carried out manually, but this can prove unreliable and expensive.

We offer machine vision inspection solutions ranging from a single intelligent camera integrated into a production-line, to multi-camera inspection systems, complete with assembly and handling systems.

From the manufacturing of special purpose machines incorporating automated visual inspection using multiple cameras, to the retrofit of vision systems to current production lines and cells, we have the expertise to provide complete machine vision solutions.

Machine vision is now an accepted part of the manufacturing process and we are here to guide you through the integration process.

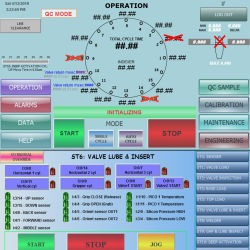

AdvanceD HMI

Our in house designed control and automation systems utilize the latest HMI technology with PC and PLC hardware to ensure all systems provide the highest possible levels of performance and communication. From standalone machine control to plant wide production and monitoring systems utilizing server- based PC networks and structured PLC plant control, we can visualize all the information so you can make informed decisions.

We design HMI to assist even the unskilled operator through the process or product set up in easy to follow steps. The HMI will also keep the operator informed as to the current status of the process.

Different parts of your production process can seamlessly share data in real time. We use Ethernet/IP, Profibus, Modbus, DeviceNet and other protocols to bring real connectivity and intelligence to your production floor so you are well informed and fully in control.

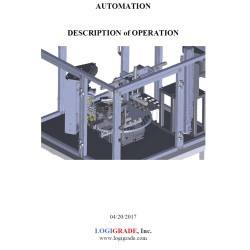

DOCUMENTATION

We design and document all the stages of our projects. Manufacturing is done in complete accordance with engineering specifications and generated drawings. Electrical design and detail schematic diagrams ensure the high quality of the control system wiring and minimizes the troubleshooting. With well-organized documentation we can quickly troubleshoot issues and easily apply any modifications if necessary.

With our projects we provide the following documentation:

- 3D mechanical detail drawings and mechanical BOM

- Electrical and pneumatic schematic diagrams with enclosure device layout including all cable marks, wire colors and numbers

- I/O list and BOM

- The programs of the PLC, HMI and other devices

- Operating and maintenance manual with colorful screenshots