Logigrade Inc

control systems with intelligent solutions

Intelligent control systems, when correctly implemented, can boost the bottom line by reducing costs, removing variables, speeding up processes, maximizing efficiency, and minimizing down-time.

Material Handling

We provide control systems for material handling industry. From simplest conveyor controls to high-level sortation, our systems are specifically designed to meet your particular requirements bringing leading-edge technology direct to your floor and integrating controls with your existing material handling equipment and legacy systems.

We work with our customers to better understand their operations and deliver a system that fits their needs. All work, including controls engineering, panel manufacturing, field wiring and installations are compliant to the electrical code. In our systems we use industry proven photo-eyes, barcode readers, RFID scanners, PLC, PC and networks.

intelligenT work

Our extensive experience of industrial and commercial electrical work guaranties the provision of complete control solution from the idea to design, implementation, startup and support. We use proven services, tools, and technologies to create solutions that deliver great performance, reliability and long-term scalability.

We prefer to use off-the-shelf software solutions to eliminate your dependency from us. We offer clean and comprehensive software programs that are easy to maintain and provide on-site and remote operational support.

We optimize workflow, manage throughput, and minimize maintenance using diagnostics and comprehensive system reporting.

Networks & Data

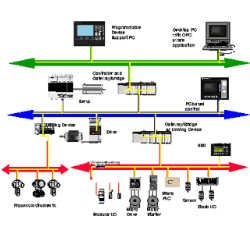

Utilizing transparent communication routing through different networks, we create integrated information environment where different parts of your production process can seamlessly share data in real time.

Connecting control systems of the production floor with your corporate network and database servers, we expand their ability for dynamic, data driven decision making.

Addition of different interfaces lets people to interact with the system remotely. It allows managers to make better, faster decisions through the provision of system-wide data, unified by a single integrated architecture.

Handy Interface

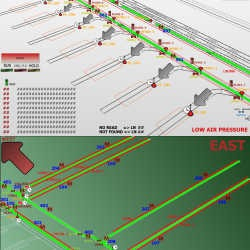

The interface system doesn't have to be a high end complicated computer system with custom programs and difficulties of maintenance. Some interface systems do require high processing power of the PCs and dynamic database control, but many of them can be simple solutions as touch screens communicating with a PLCs. Some of the advantages of the latter are low cost, and ease of expansion. Also, these are off-the-shelf products with common software, and you will always find dozens of integrators that can modify your system.

A simple low-end touch screens can provide plenty of information for operators to be in control of the situation and maintenance personnel to quickly troubleshoot the system.